- #MASTERCAM X5 LATHE TRAINING TUTORIAL HOW TO CREATE A#

- #MASTERCAM X5 LATHE TRAINING TUTORIAL MANUAL AT ANY#

Mastercam X5 Lathe Training Tutorial Manual At Any

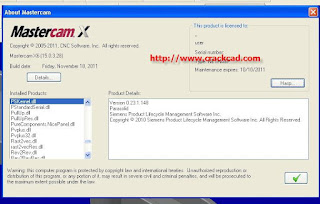

Reserves the right to make improvements to this manual at any time and without notice. All rights reserved Software: Mastercam X5 Author: Mariana Lendel ISBN: 978-1-92 Revision Date: OctoNotice In-House Solutions Inc. Mastercam X5 Lathe Training Tutorial Copyright: 1998 -2010 In-House Solutions Inc.

In no event will In-House Solutions Inc. Should the manual prove defective following its purchase, the buyer (and not In-House Solutions Inc., its distributer, or its retailer) assumes the entire cost of all necessary servicing, repair, of correction and any incidental or consequential damages. Manual is sold or licensed "as is." The entire risk as to its quality and performance is with the buyer. Makes no warranties, either express or implied, with respect to this manual or with respect to the software described in this manual, its quality, performance, merchantability, or fitness for any particular purpose.

The Lathe Training Tutorial is ideal for beginners and current Mastercam. The material emphasizes the machinability of parts with suggested fixtures, setup sheets & more. This Combo Pack includes the Mill 2D, Mill 3D and Lathe Training Guides and provide all the instructions you.The Mastercam X5 Lathe Training Tutorial consists of 9 brand new part-oriented tutorials, and 9 practice exercises that provide users with an excellent foundation in Lathe. Windows, Windows XP, Windows Vista and Windows NT are registered trademarks of Microsoft Corporation.Mastercam X5 Mill Level 1 Training Tutorial. Microsoft, the Microsoft logo, MS, and MS-DOS are registered trademarks of Microsoft Corporation NSee is a registered trademark of Microcompatibles, Inc.

E-1TUTORIAL #3 Objectives: The Student will design a 2-dimensional drawing by: !Create lines using polar positioning. 10-1General Notes.B-1 Creating a Lathe Tool Library.C-1 Editing a Lathe Tool Library.D-1 Quiz Answers. A-1 Tutorials Tutorial #1. Create and edit tools as required by the part operations and dimensions.Lathe Training Tutorial Contents Getting Started. Move the solid model to it s machine orientation and create any necessary 2D geometry.

The Student will simulate the toolpaths using Mastercam's Verify and Backplot by: !Defining a 3-dimensional cylinder the size of the workpiece. !Cutoff toolpath to cut the part off at a desired position. !Grooving at an angle with fillets in the corners of the groove !Finishing toolpath with multiple passes using a tool with a round insert. !Canned Finish toolpath to remove the leftover material from the roughing toolpath. !Canned Roughing toolpath to remove the bulk of material. The Student will create lathe toolpaths consisting of: !Facing toolpath to machine the face of the part.

See Getting started page A-6 for further information. It will show you where the part origin is. Make sure that the Grid is enabled. See Getting started page A-4 for details. This tutorial takes approximately 50 minutes to complete.SETTING UP THE GRAPHIC USER INTERFACE Before starting the geometry creation we should customize the toolbars to see the toolbars required to create the geometry and machine a part. !Running the Verify to simulate the tool cutting from the solid model.

Mastercam X5 Lathe Training Tutorial How To Create A

Select Lathe diameter +D +Z.CREATE THE OUTSIDE PROFILE In this step you will learn how to create a line knowing an endpoint, the angle and the length. Select Planes from the Status Bar. See Setting the Construction and Tool Plane to DZ on page A-10 in Getting Started. Change the Cplane to +D +Z. Repeat this command to make it visible again.NOTE: Because the part is symmetrical in the Z-Axis, you will only draw 1/2 of the total part. From the keyboard, press Alt + O keys simultaneously to hide it.

Using the mouse scroll wheel, roll the wheel backwards to unzoom, to see the Grid and the line we just created as shown in Figure 2.1.1.NOTE: During the geometry creation of this tutorial, if you make a mistake you can undo the last step using the Undo icon.You can undo as many steps as needed. Use the Fit icon to fit the drawing to the screen. Enter in the coordinates 0,-3 (Enter).NOTE: When working with the +D, +Z plane, enter in the coordinates in this order (D,Z).Select the Apply button to stay within the command.

Figure: 2.4.12.5 Sketch the final line In this next step we will enable an option found in the autocursor configuration to help us sketch a horizontal line.Select the Config button in the Autocursor toolbar.Ensure that you have Horizontal/Vertical enabled as shown below.Select the Ok button to exit the Autocursor Settings dialog box. For now we will use 1.25.: Select the Endpoint as shown in Figure 2.4.1. Figure: 2.3.12.4 Create the 135° line NOTE: The length on this line is not important as we will trim the lines later on. Figure: 2.2.1Make sure that when selecting the origin, the visual cue of the cursor changes as shown.Select the Apply button to stay within the command.: Select the Endpoint as shown in Figure 2.3.1. First and then press Delete from the keyboard.: Select the Origin as shown in Figure 2.2.1.

Figure: 2.5.2TRIM THE LINES In this step, we will trim the intersecting lines left from step 2.Enable the Trim 2 Entities button. The part should appear as shown in Figure 2.5.2. Figure: 2.5.1 Sketch the line to a point beyond the 135° angled line as shown below.Select the Ok button to exit the command.

0 kommentar(er)

0 kommentar(er)